WoodSafe : Un choix écologique pour la gestion des déchets médicaux

WoodSafe

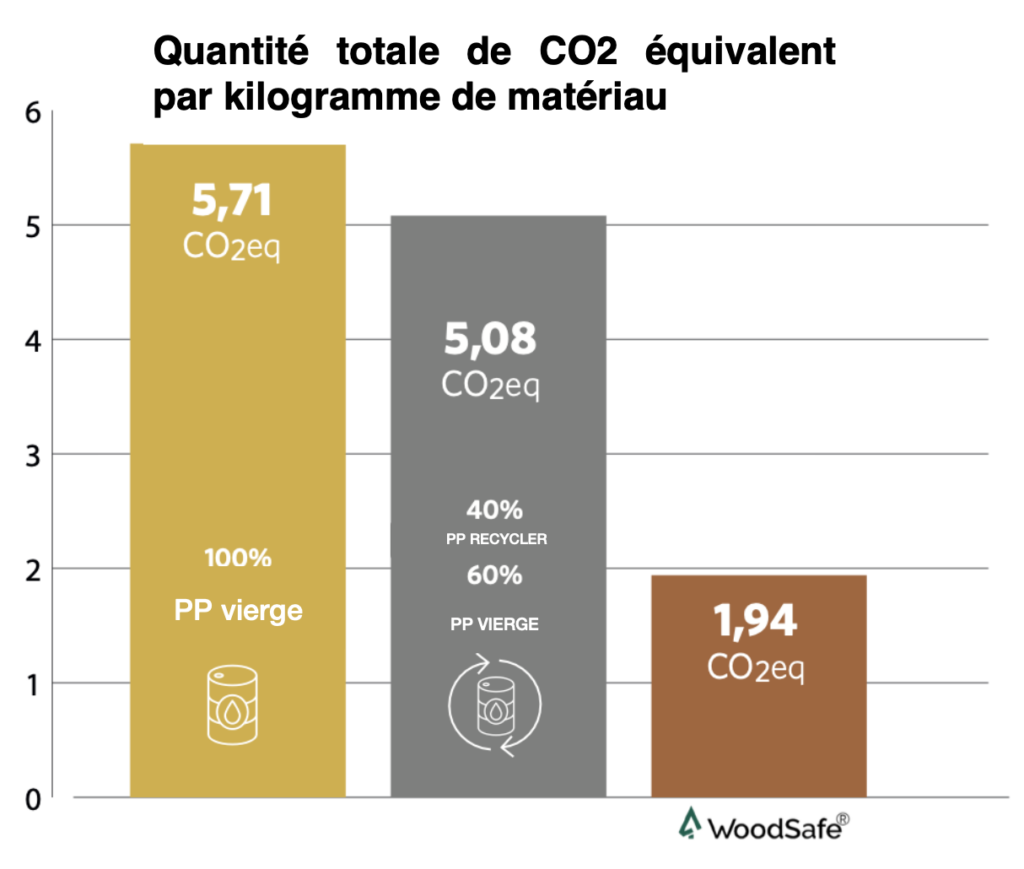

WoodSafe est un conteneur pour déchets médicaux basé sur des matières premières renouvelables issues de la forêt et qui permet de réduire les émissions de CO2 de 66 %

Découvrez comment WoodSafe contribue à un avenir plus vert tout en répondant aux besoin cruciaux des établissement de santé.

WoodSafe

WoodSafe est fabriqué a partir d’un biocomposite du Laboratoire Store Enso spécialiser dans une large gamme de polymères, les avantages du polymère sont la flexibilité et la durabilité ainsi offrant une liberté de conception. Les avantages des fibres de bois résident dans leur solidité et leur aspect naturel mais également dans leur faible empreinte carbone.

3eme plus grande sources d'émissions de CO2

Les conteneurs Dasri représentent actuellement une grande partie de la consommation de plastique dans le secteur de la médecine. Après les gants d’examen et les tablier jetables, les conteneurs Dasri sont le produit le plus important en termes de quantité incinéré par ans. En remplaçant les conteneurs Dasri actuel par celle de WoodSafe et qui sont produit avec des matériaux biocomposites, nous réduisons de moitié l’empreinte carbone de l’un des plus grands produit plastique consommé .

Calculateur de co2

Vers une Pharmacie responsable

01. Les Défis de durabilité dans l’industrie pharmaceutique

L’industrie pharmaceutique est confrontée a des défis unique en matière de durabilité. De la gestion des déchets a la consommation d’énergie intensive, les pratique traditionnelles peuvent avoir un impact significatif sur l’environnement. Cependant ces défis peuvent être transformés en opportunités pour innover et créer des solution durables

02. Réduction des émissions de CO2

Une des principales voies pour une industrie pharmaceutique durable est la réduction des émissions de dioxyde de carbone. En utilisant des sources d’énergie renouvelable et en. investissant dans des technologies plus propres, les entreprises pharmaceutiques peuvent significativement diminuer leur empreinte carbone.

03. Utilisation de matières premières durables

Integrer des matières premières durable est une étape clé vers une pharmacie responsable; Des emballages biodégradables aux matériaux de production issus de sources renouvelables, l’industrie peut réduire son impact environnemental tout en garantissant la qualité des produits pharmaceutique.

04 .Innovation dans la recherche et le développement

Une approche durable ne se limite pas au opération quotidiennes elle doit également être intégrée dans la recherche et le développement de nouveaux produits. En investissant dans des technologie plus vertes et des processus respectueux de l’environnement; l’industrie peut continuer a innover tout en préservant la planète.

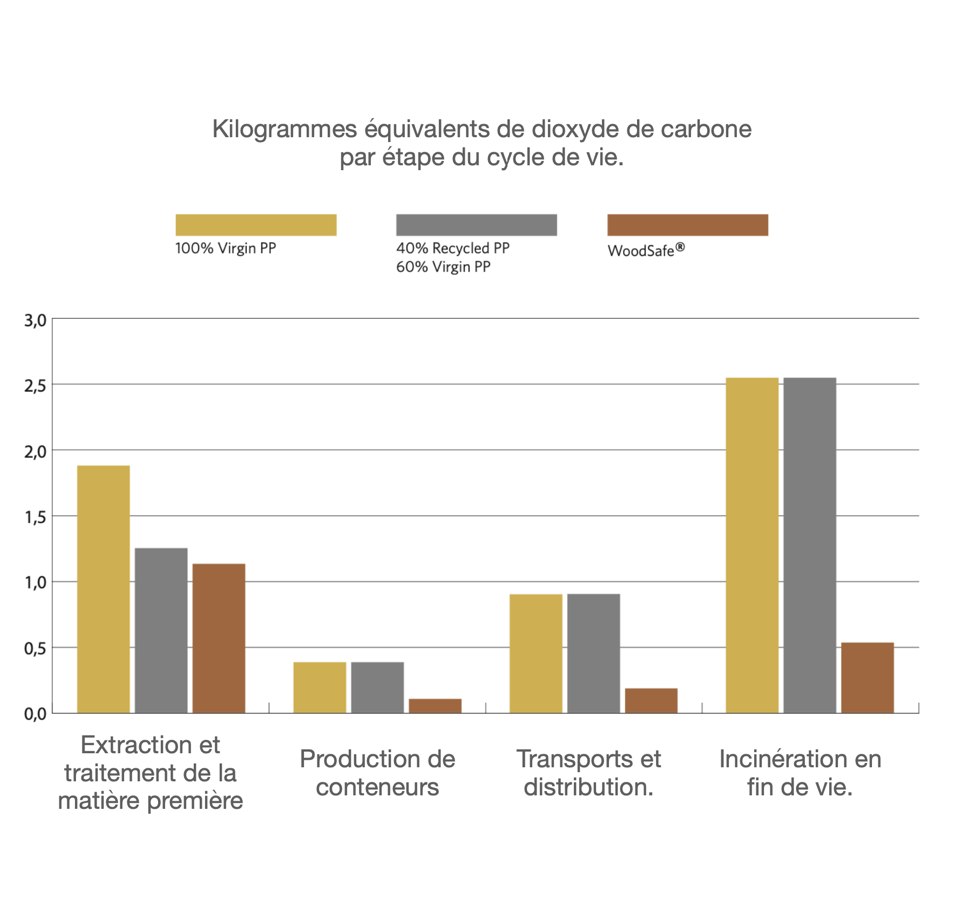

Cycle de vie

Woodsafe a les émissions de CO2 les plus basses durant la production en raison de son matériau biosourcé et de son traitement en Suède. En production, le PP (Polypropylène) vierge et le matériau avec une partie de PP recyclé sont supérieurs à Woodsafe, principalement en raison du PRP plus élevé de l’électricité en Europe par rapport à la Suède où Woodsafe est produit. Le PP est souvent produit dans le sud de l’Europe. En ce qui concerne le transport et la distribution, l’étude considère un scénario où le consommateur final est en Suède. Woodsafe a un bilan inférieur en CO2 car il est produit plus près du marché. L’incinération en fin de vie contribue le plus aux émissions de CO2 du matériau à base d’huile.